How to Check Your Generator Before a Freeze

For homeowners and businesses in East Canton, a severe freeze or a winter storm often means relying on a generator for essential backup power. When the utility grid fails, your generator is the one component standing between comfort and serious disruption. However, a generator is a complex machine that sits idle for most of the year, and if it is not properly maintained and prepared, it will likely fail precisely when you need it most. The worst time to discover a maintenance issue is during a zero degree blizzard.

Winterizing your generator is more than just topping off the fuel; it is a critical, multi step maintenance routine that addresses the fuel system, the battery, the engine, and the connection to your home. Taking the time now, before the extreme cold arrives, ensures that your unit will start quickly, run reliably, and deliver power safely to your property when the time comes. This preparation is an investment in your peace of mind and the continuous safety of your family and essential systems.

The Importance of the Pre-Freeze Test Run

The single most important pre-winter check for any generator, whether it is a portable unit or a whole home standby system, is a thorough test run. This step verifies that all components are working together under load conditions.

A test run should last for at least 15 to 30 minutes, allowing the engine to reach its full operating temperature. During this period, you should listen closely to the engine. Pay attention to any unusual knocking, sputtering, or rough idling. A healthy engine should run smoothly and maintain a consistent speed. Irregular noise often indicates old fuel, a carburetor issue, or a problem with the spark plug. Addressing these minor engine issues now prevents a full startup failure in an emergency.

For standby units, observe the transfer switch mechanism during the test. Standby generators should be programmed to run a short diagnostic test automatically, usually once a week. The manual test run confirms the engine starts and the unit is generating voltage. If your unit is a whole home system, running it manually allows you to confirm it is ready to power essential loads. If your generator does not start easily or runs rough, stop the test and call a professional service technician immediately.

Fuel and Fluid Management: The Lifeline of the Generator

Generators rely on clean, reliable fuel and properly conditioned fluids to start and run efficiently, especially in cold temperatures. Neglecting these areas is the most common cause of winter startup failure.

If your generator runs on gasoline, the fuel is your biggest vulnerability. Gasoline begins to degrade and form gummy deposits within a few months, and these deposits can clog the carburetor and fuel lines. Before the cold sets in, ensure the fuel tank is full and treat the fuel with a quality fuel stabilizer. Running the generator for a few minutes after adding the stabilizer ensures it circulates throughout the entire system. For portable units, only use fresh, clean fuel. Never use gasoline that has been sitting in a can for more than six months.

Need a generator installation? Click here for our generator installation service.

For generators that run on natural gas or propane, verify the fuel supply lines are secure and free of leaks. Propane tanks should be kept as full as possible, as the pressure inside the tank drops significantly in freezing temperatures, which can prevent the unit from drawing enough fuel. For a natural gas line, ensure the shutoff valve is accessible and verify that the line itself is not compromised by rust or physical damage.

Engine oil also requires attention. Cold weather thickens standard engine oil, making it difficult for the engine to crank and damaging the internal components during startup. If you live in an area prone to severe cold, consider switching the oil to a synthetic variety specifically designed for low temperature operation, as recommended by the manufacturer. Check the oil level before the test run and again afterward, topping it off as needed.

The Critical Electrical and Battery Check

The battery is the weakest link in any electric start generator, as cold weather severely impacts battery performance. A battery that works fine in September may fail entirely when the temperature drops below freezing.

For all electric start units, thoroughly clean the battery terminals. Corrosion, which appears as white or greenish buildup, acts as an insulator, preventing the battery from delivering its full power to the starter. Use a wire brush to remove all corrosion, then coat the terminals with an anti-corrosion grease or terminal spray. Ensure the battery cables are firmly secured and are not frayed or damaged.

Check the battery voltage with a multimeter. A healthy 12 volt battery should read close to 12.6 volts. If the voltage is low, the battery should be charged fully. For standby generators, the battery is continuously charged by a trickle charger, but you must ensure this charger is functioning correctly. If the charger is failing, the battery will be dead when the power goes out. For portable units, consider removing the battery and keeping it on a battery tender in a warm, dry area until it is needed.

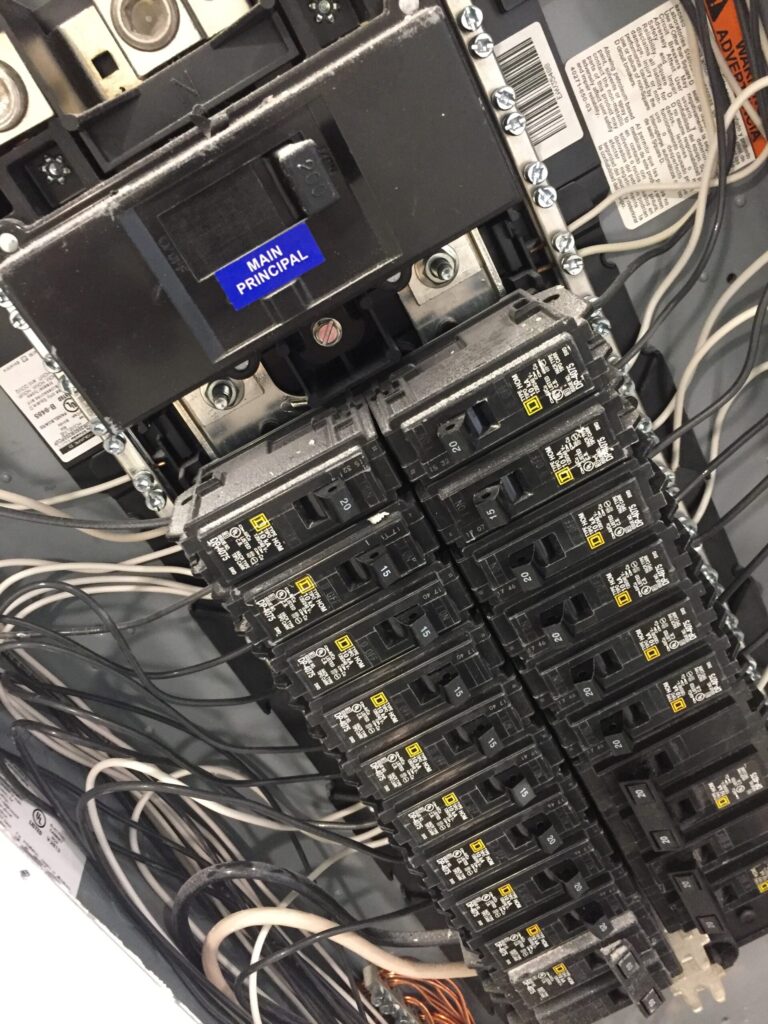

Beyond the battery, inspect the electrical connection to your home. If you have a standby unit, the Automatic Transfer Switch, or ATS, is the critical piece of equipment. Ensure the ATS enclosure is clean, the indicator lights are functioning, and the physical wires connecting to the panel are secure. If you use a portable unit, inspect the inlet box and the generator cord for any cracks, damage, or wear that might allow moisture intrusion or compromise safety.

Physical Placement and Weatherproofing

The physical location and immediate environment of your generator are essential factors in its winter reliability. Both portable and standby units require proper ventilation and protection from the elements.

Standby generators are typically housed in a weather resistant enclosure, but you must ensure the unit’s vents and exhaust are completely clear of debris, particularly snow and ice. During a heavy snowfall, snow accumulation can block these vents, causing the unit to overheat or leading to carbon monoxide buildup. Keep the area around the generator clear of vegetation and ensure the enclosure door seals are intact to prevent rodents from seeking shelter and damaging internal wiring.

Want to know the value of having a generator? Click here for more information.

For portable generators, never, under any circumstances, run the unit inside your home, garage, or any partially enclosed structure. The carbon monoxide produced is an odorless, deadly gas. When running a portable generator, place it at least 15 to 20 feet away from the home and any windows, doors, or vents to prevent fumes from entering the living space. Portable units should also be protected from direct precipitation using an open sided canopy or a specialized generator tent, ensuring airflow remains unrestricted.

Ensure your entire setup, from the generator to the transfer switch or power inlet box, is stable and secured. Freezing and thawing cycles can shift the ground, potentially compromising the base of a standby unit. If the unit is leaning or the concrete pad has cracked, it may require professional attention.

Professional Service: The Ultimate Pre-Season Check

While the homeowner can perform basic checks, a full pre-freeze service check by a licensed professional is the best way to guarantee reliable operation and ensure the unit’s safety systems are functional. Generators are high voltage devices, and attempting to service the internal electrical components or the connection to the transfer switch without training is extremely dangerous.

Gragg Electrical Services provides comprehensive generator maintenance that goes far beyond a simple visual check. We inspect the alternator, voltage regulators, and electrical connections inside the control panel. We verify the ATS functionality, ensuring it senses an outage and transfers power correctly, and that it safely isolates your home from the grid to prevent backfeeding, a lethal danger to utility workers.

We check and replace the air filter and spark plugs as needed, which is vital for cold weather starting. Furthermore, we can update the generator’s firmware and check the warranty status. Regular professional maintenance ensures the generator remains in peak condition, extending its lifespan and preventing catastrophic failure during an actual power outage. This service is a small investment that protects a much larger one.

A generator is the ultimate safeguard against winter power outages in East Canton, but only if it is meticulously maintained. The combination of fuel degradation, battery weakness, and potential icing can easily sideline an unprepared unit. By proactively performing a test run, managing fuel and fluids, checking the battery and electrical connections, and securing the unit’s physical location, you significantly increase the probability of a successful startup when the moment comes. Do not risk your family’s comfort and safety during a severe cold snap; schedule your professional pre-freeze generator check today to ensure you are truly prepared.